Metals

One break in your process can halt production. High-temperature, high-load and wet conditions can place severe demands on metal-processing equipment. Whether you want to improve energy efficiency for greater output or lower emissions, or to cut maintenance costs by enhancing equipment protection, Shell offers a wide range of products and services designed to make a real difference to your margins.

Shell Lubricants for Metals

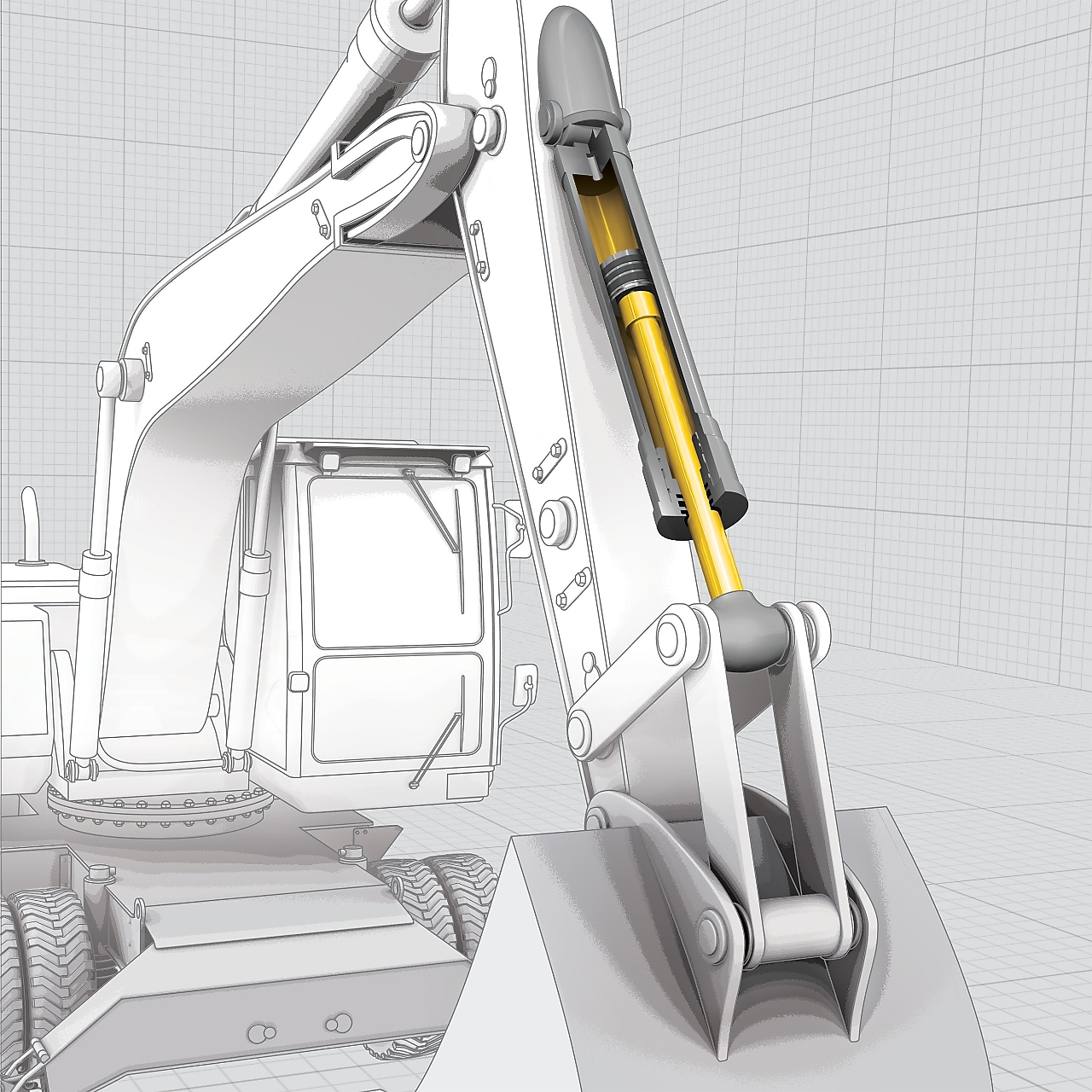

Hydraulic fluids

Find out how Shell hydraulic fluids can maintain or even improve the efficiency of your hydraulic systems with the latest synthetic, ashless technology.

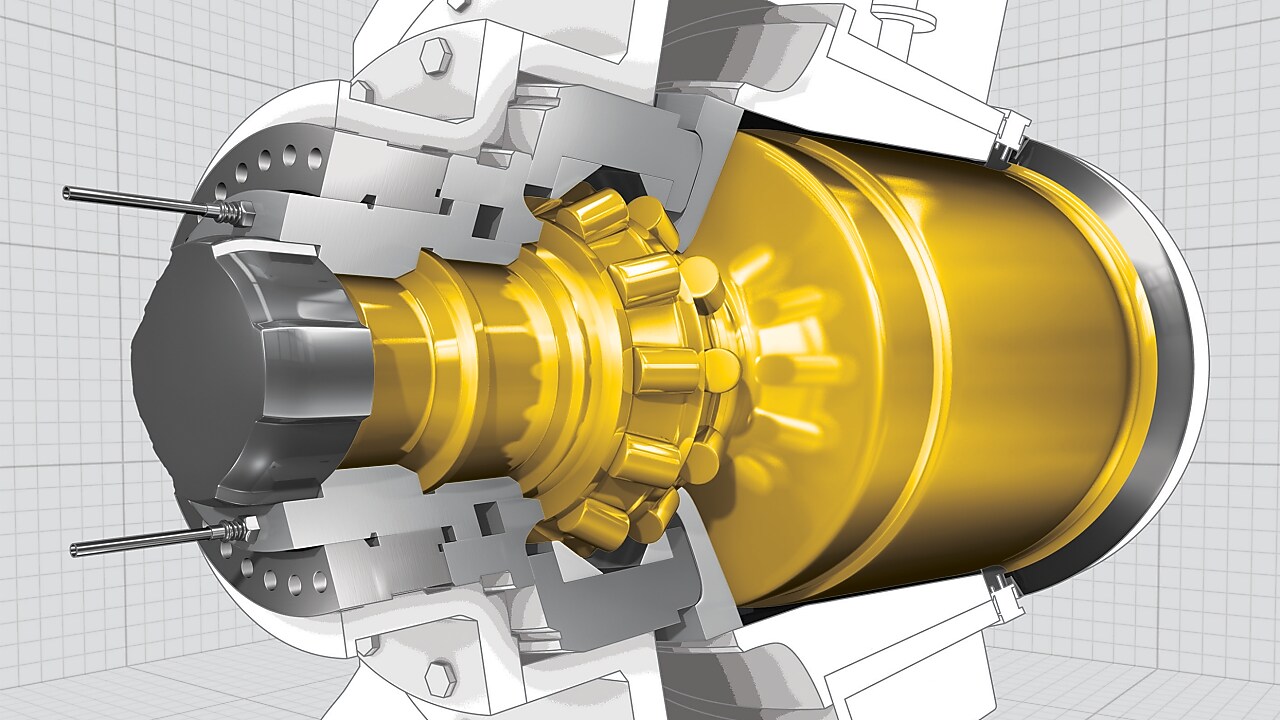

Baosteel Group Corporation, China

Baosteel was experiencing issues with its bearings and lubricant filters. The use of Shell Morlina helped to save a reported US$53,185 in 2009.

Egyptian Iron & Steel Company, Egypt

The Egyptian Iron & Steel Company switched to Shell Albida HD 2 with a calculated saving of US$2,688,000 per annum.

Download the Iron and Steel company case study

Southern Steel Corp, Vietnam

Changing to Shell Gadus helped this steel company reduce breakdowns and improve uptime. Result: reported annual saving of US$5,145.

Download the Southern Steel case study

Metals Product Range

Choosing the right lubricants and services for your business can help to make a real difference to the efficiency of your entire operation.

Download the Metals product range brochure

Services

Shell LubeAdvisor

Our experts can advise you on which oil to use to improve efficiency and reduce your operating costs.